New Bruinswick

Maintenance

Alert

Cleaning

Painted Surfaces

All exterior paint work and inner doors should be cleaned using a solution of mild detergent in water. Do not use abrasive cleaners or solvents.

Interior and Shalves

The interior panels and shelves are made of stainless steel. They may be cleaned using a recommended cleaning solvent, 70% Isopropyl alcohol 30% distilled water applied with a lint free cloth.

Air Intake Grille and Filter

The air intake grille must be cleaned regularly to keep it free from dust and debris. Under normal conditions, clean the grille once every three months. If the area around the freezer is very dusty or dirty, clean the grille more often. Brush the grille with a soft brush and, if a vacuum cleaner is available, vacuum the dust from the grille.

NOTICE! Risk of Material Damage

- Serious damage to the freezer may result if the air intake is blocked. Check that there is no obstruction of the airflow to the freezer. The air intake filter must also be cleaned regularly.

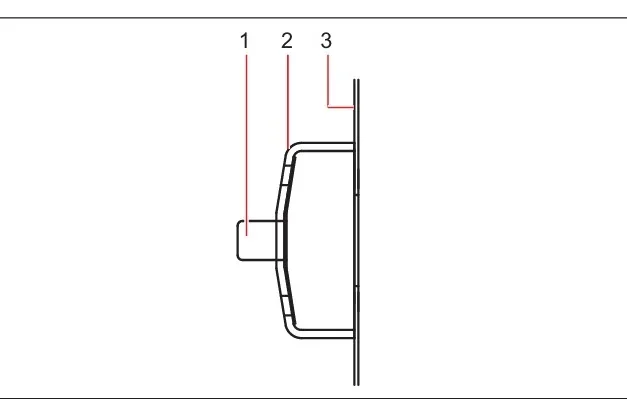

- Remove the filter from behind the grille by turning the thumbscrews 1/4 turn and opening grille downward. The filter should be washed in warm soapy water and left to air dry before replacing.

Heated Vent Port

- There is an electrically-heated vent port in the freezer which must not be allowed to become blocked or sealed off.

- Over a period of a few weeks, depending on how often the freezer is being used, a small mushroom of ice will form around the end of the vent port. If the vent port is allowed to become blocked, a vacuum will be created when the door is closed. It will not be possible to open the door or lift the lid until the vacuum has leaked away through the seal, which can take up to two hours due to the high quality of the seals.

- The vent port is located on the left-hand side of the freezers.

- If the door cannot be opened, clear the vent port by pressing the manual plunger on the outside of the air vent.

Door or Lid Seal

Be sure to treat the door or lid seal with care. Avoid damaging this seal in any way. The freezer cannot operate properly with a defective seal.

- It is advisable to wipe both the seal and the surface against which it seals with a soft dry cloth once a month.

Routine Maintenance

Lubrication

Every 12 months the outer door hinges and the handle mechanism should be lightly lubricated using general-purpose oil or spray grease.

Defrosting

After an extended period of operation, defrosting may become necessary:

NOTICE! Risk of material damage: Do not attempt to chip or scrape the ice with a sharp instrument. Allow the ice to melt naturally.

- De-activate the alarm by switching the battery (alarm) switch (located behind the lockable panel on the front of the freezer) to off (O).

- Unplug the freezer from the mains/electrical supply.

- Leave the inner and outer doors or lids open.

- Allow the accumulated ice to melt.

- Mop up the resulting water.

- Dry and decontaminate the interior of the freezer.

- When defrosting is complete, reconnect the freezer to the mains/electrical supply.

- Turn the mains/power switch on (I) and re-activate the battery (alarm) switch.

Removing the Inner Doors

The inner doors of the freezer can be removed for defrosting and cleaning.

- Fully open the outer door of the freezer.

- Fully open the inner door.

- Lift off inner door from hinges and set aside.

- Repeat procedure for each door.

Replacing the Inner Door

- Fully open the outer door of the freezer.

- Fit door to hinge pins and close.

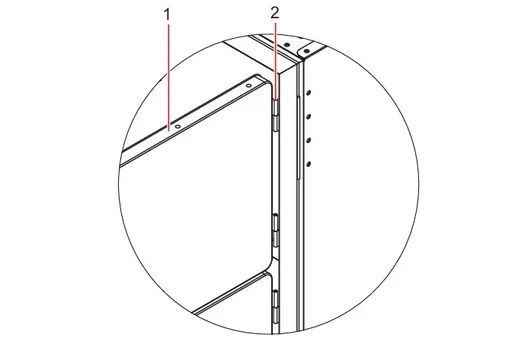

- Check to ensure that inner door gasket is sealing against the freezer trim.

- If required, adjust the latch retainer by loosening the screws and moving forward or backwards.

- Close outer door.

Electrical Components

WARNING! Risk of Personal Injury

- During routine maintenance, care must be taken to avoid any damage to the gaskets and sealing grommets of these enclosures; also check the gaskets and sealing grommets routinely to ensure their integrity. Should any damage or deformity be detected, the gasket and/or sealing grommet must be replaced immediately.

- Failure to observe this safety warning will invalidate the warranty and could result in a dangerous situation.

Lamps

Regularly Check the Indicator Lamps:

- Press the Alarm Test/Mu8te key. All of the indicator lamps should illuminate, and the display should read 8888.

Alarms

Regularly check the alarms:

- Press the Alarm Test/Mute key. The temp indicator should illuminate and the audible alarm should sound.

Battery Replacement

NOTICE! Risk of Material Damage

- There are no user controls behind any panels. The removal of any other part or panels from the freezer by anyone other than a qualified, authorized Service Engineer may invalidate the warranty.

- Use only a replacement battery of the correct type and part number.

- The battery must be fitted so the terminals correspond to the polarity labels on the electrical panel.

The YUASA-NP6 V 2.8 Ah batter is mounted on the electrical panel. This is located behind the right-hand base cover.

To replace the battery:

- Switch off the mains/power switch and disconnect the mains/power supply.

- Remove the side cover and the battery clamp securing the battery to the electrical panel.

- Disconnect the battery terminals.

- Install the new battery, fixing screws, and the side cover.

- Be certain, when reconnecting the battery, to respect the correct polarity (red is + positive and black is - negative).

- Reconnect the freezer to the mains/power supply and turn the mains/power switch on.

Fuses

Fuses must be replaced by an Eppendorf approved service engineer. Contact Eppendorf Service.

Troubleshooting

General Errors

| Symptoms/Message | Cause | Remedy |

|---|---|---|

| Door will not open | 1. The door handle is locked. 2. The heated vent port is blocked. | 1. Unlock the door handle. 2. Break up the ice in the vent port using the plunger. If the door will not open: Call Eppendorf service. |

| Filter-Clean LED lights up | Filter is contaminated | Clean the Filter. If the LED remains lit: Call Eppendorf service. |

Error Messages

Your electronically-controlled freezer incorporates the unique Systems Monitoring And Reporting Technology (S.M.A.R.T. Plus™) self-diagnostic software to diagnose faults in its electronic systems, its probes and/or its refrigeration system.

This table interprets error codes that may appear in the control panel display:

| Symptom/Message | Cause | Remedy |

|---|---|---|

| E-01 | PT100 Probe 1 failure. This probe, located inside the freezer cabinet, indicates cabinet temperature. | Call Eppendorf service deparment. |

| E-02 | Probe 2 failure. This probe monitors the cascade condenser. | Call Eppendorf service department. |

| E-03 | This probe monitors the air-cooled condenser. | Call Eppendorf service department. |

| E-04 | Air cooled condenser temperature too high: 1. Filter may be blocked. Ambient temperature may be too high. 2. If alarm continues to sound: Fan may have filled or water supply not turned on, insufficnet flow, regulated valve no opening or defective. | 1. Clean filter according to the instructions. 2. Cool the Room. |

After a Mains/Power Failure

- If mains/power is interrupted, the POWER-FAIL indicator lamp will illuminate. In addition, the audible alarm will sound and the display will flash at approximately 10-second intervals.

- When mains/power is restored, both alarm and light will automatically be cancelled.

- If mains/power has been interrupted for only a short time, the internal temperature of the freezer will not have risen above the temperature setpoint (the user-set alarm threshold), so normal operation will be resumed immediately.

- If the interruption was long enough for the internal temperature to rise above the temperature setpoint, the TEMP-ALARM indicator will illuminate. If the internal temperature does not fall below the temperature setpoint within the programmed time after mains/power was restored, the audible alarm will sound again. The TEMP-ALARM indicator will extinguish when the internal temperature reaches the High Alarm temperature set point.

Interior Warming

- If the lid or door is left open long enough for the internal temperature to rise above the temperature setpoint, the same effects will be observed as described above regarding power failure.

- To minimize the risk of this happening, the lid or door should only be opened when necessary, for a short period of time.

- The upright freezers are fitted with internal doors which latch shut, minimizing temperature rise when the outer door is opened. Chest freezers are fitted with inner insulating lids to ensure efficient running of the freezer. The lids should remain fitted at all times when the freezer is running.